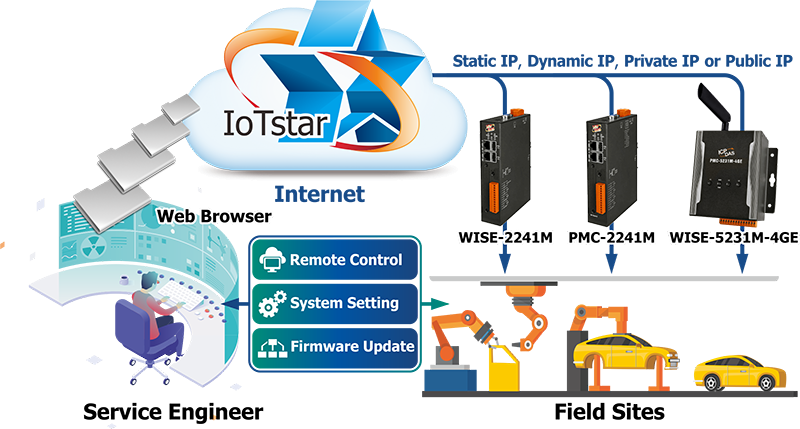

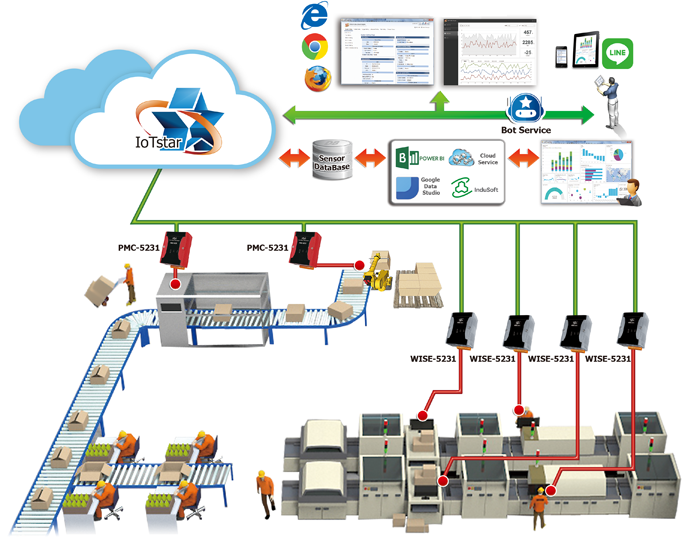

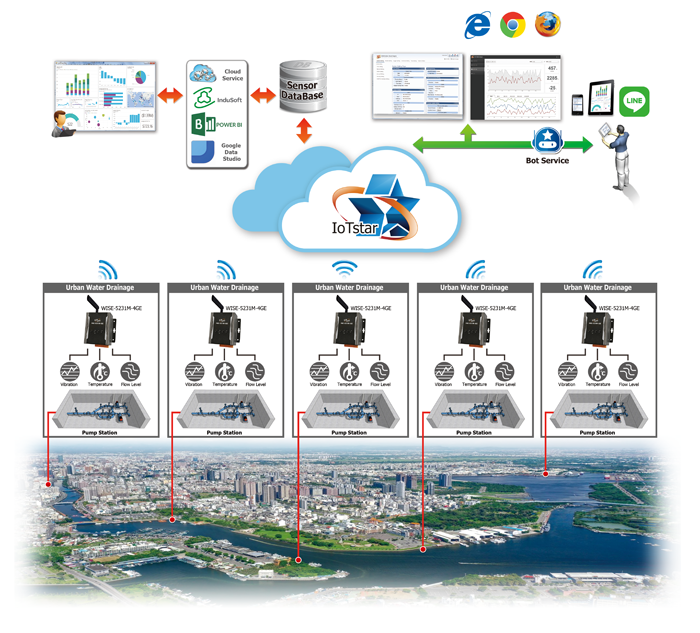

IoTstar is a software package developed for the WISE/PMC/PMD controllers for a variety of Industrial IoT applications. IoTstar can be installed on a general PC platform and works as a Private IoT Cloud system, or on the VM (Virtual Machine) platform of Microsoft Azure, IBM Bluemix, Google Cloud or Amazon AWS, etc. and works as a Public IoT Cloud system.

Using IoTstar to build the IoT Cloud system, it can provide the following services:

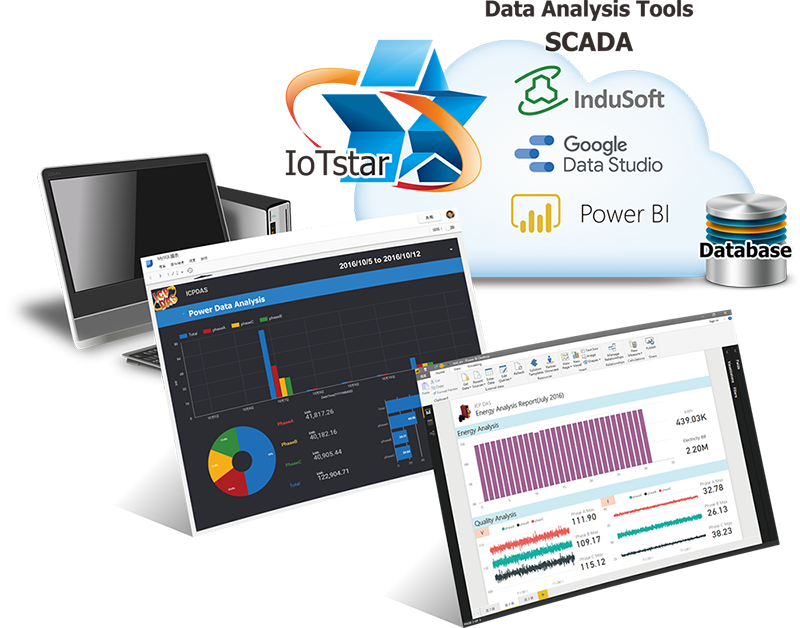

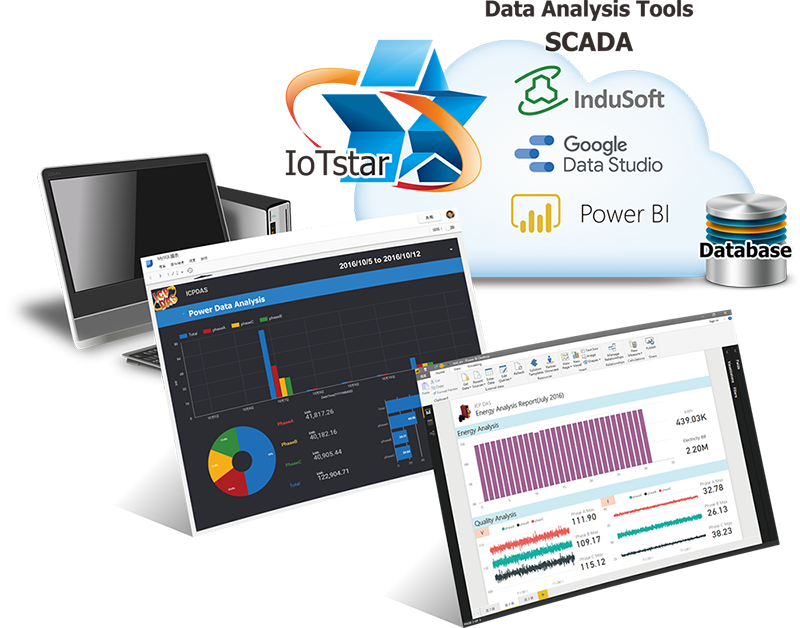

During the IoT Cloud system development, there is no-programming-required, and the system setting can be completed only through the web interface operation. In additon, through the SQL command, IoTstar can be quickly integrated with the Cloud platforms, data analysis tools (Power BI, Google Data Studio or SCADA system etc.) to help users quickly build the “IoT + Big Data” Cloud application and significantly reduce the time and cost of building the “IoT + Big Data” Cloud application.

System Architecture

Trial versions available

New Optional add-ons: Dashboard Service + Report Service, in addition to the Bot service for Notifications

Expandable for up to 200 or 500 controllers

Flexible installation environment supported to quickly set up IoT Cloud system

According to the needs of the field site, the installation environment can be flexibly selected.

IoTstar can be installed on the VM (Virtual Machine) platform of the Public Cloud platform such as: Microsoft Azure, IBM Bluemix, Google Cloud or Amazon AWS to implement the Public IoT Cloud system on WISE/PMC/PMD controllers. It can reduce the loading for maintaining the IoT Cloud operating environment.

If the user concerns about the environment of the system operation or data storage, the IoTstar can also be installed on a private Windows PC (Windows 7/8/10, Windows Server) to implement the Private IoT Cloud solutions on the WISE/PMC/PMD controllers, and then the user can manage the environment by himself.

No more programming! Using Browser to set up the IoT Cloud system

Only by a few clicks on Web page of IoTstar and WISE/PMC/PMD controller to complete the setting of IoT Cloud system.

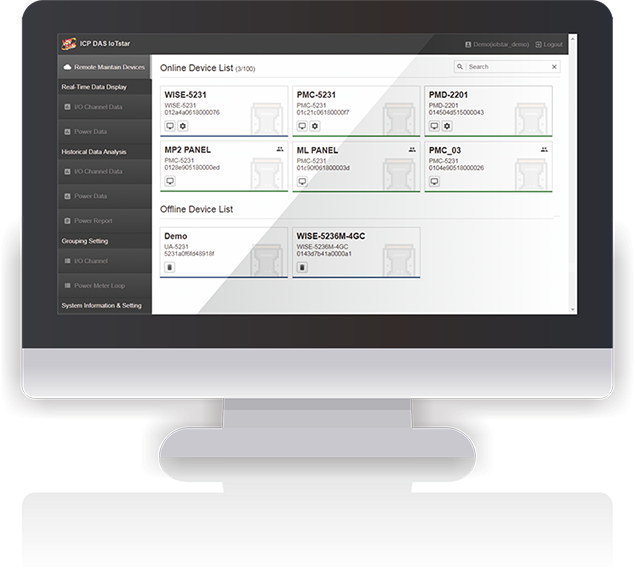

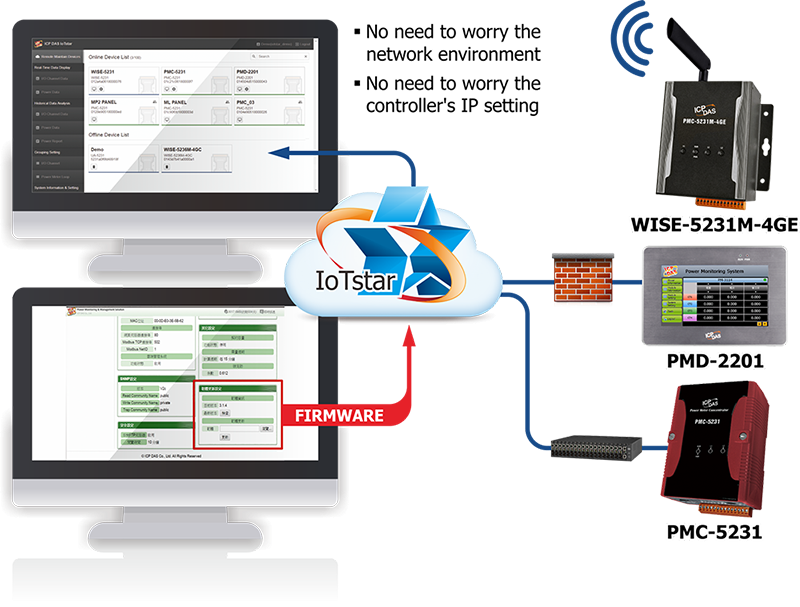

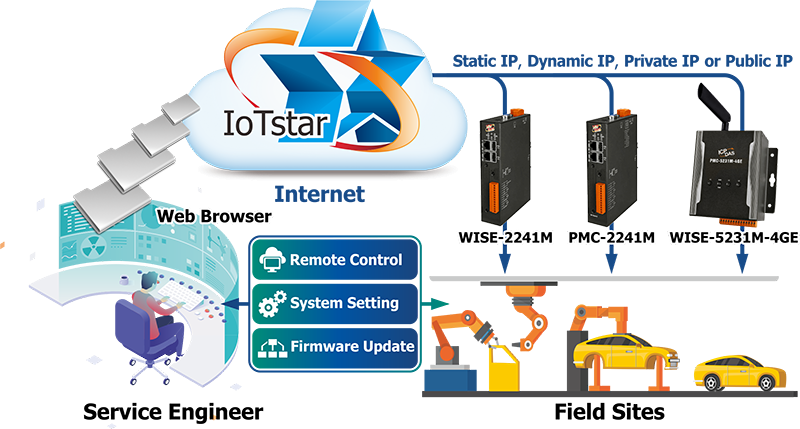

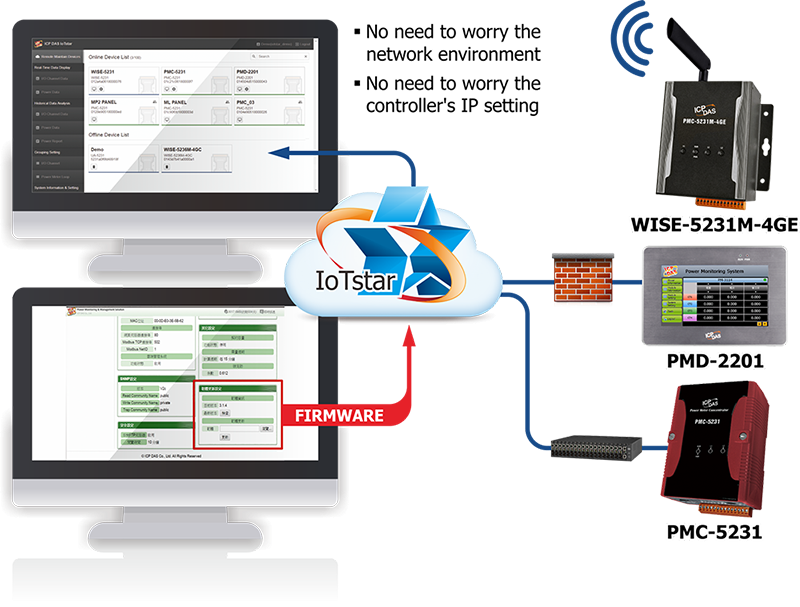

Controller Remote Access/Maintenance Service

With IoTstar, users do not need to worry about the network environment of the WISE/PMC/PMD controller, regardless of whether the controller uses the static IP, dynamic IP, virtual IP or physical IP, user can perform the status monitoring, system setting adjusting, and update the firmware of the controllers through the web interface provided by IoTstar. It can reduce the time and cost of personnel travel due to performing the maintenance operations of controllers.

Sensor Data Collection Service

Sensor data collection and import the data into the database at the cloud

With IoTstar, the Sensor Data Service can be performed to collect the Historical and Real-Time sensor data (and/or Power data) from the WISE/PMC/PMD controllers, and import the data to the Database in the Cloud. The users can quickly setup the Data Lake for the IoT and Big Data applications. The users can also modify the data in the database to change the status of the DO/AO channel of the sensor connected to controllers through the SQL command.

Please note: The Service support the mechanism of " Historical Sensor data automatically send back (to IoTstar) & recovery when disconnected network is resumed.”

Support SQL interface to speed up the integration of OT and IT systems

With the support of SQL command interface, the sensor data stored by IoTstar can be connected easily with the third-party data analysis tools (such as: Power BI, Google Data Studio, SCADA system), and ERP/MES systems. It can assist user to integrate the OT(Operational Technology) and IT(Information Technology) systems quickly and seamlessly, so that comprehensive and complete information regarding system operations can be collected with ease.

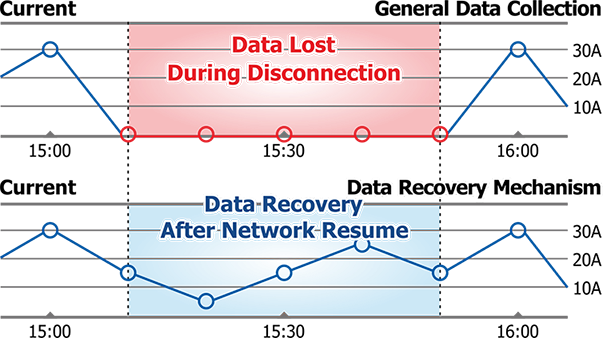

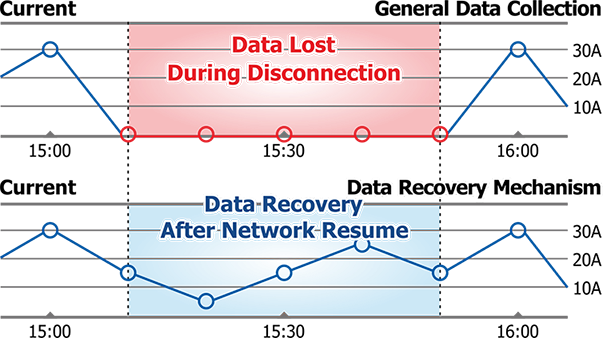

Sensor Data Recovery Mechanism

For general data collection, the sensor data will be sent to the control center and imported into the Database at cloud. But when the network experience a disconnection, the data transmitted during the disconnection period will be lost. "IoTstar (with WISE/PMC/PMD)" supports the Sensor Data Recovery Mechanism. When experiences network disconnection, all data will be stored in the SD cards in WISE/PMC/PMD. And when the network return to normal status, the data stored in SD card will be re-sent to IoTstar, and imported into Database to ensure the integrity of historical data.

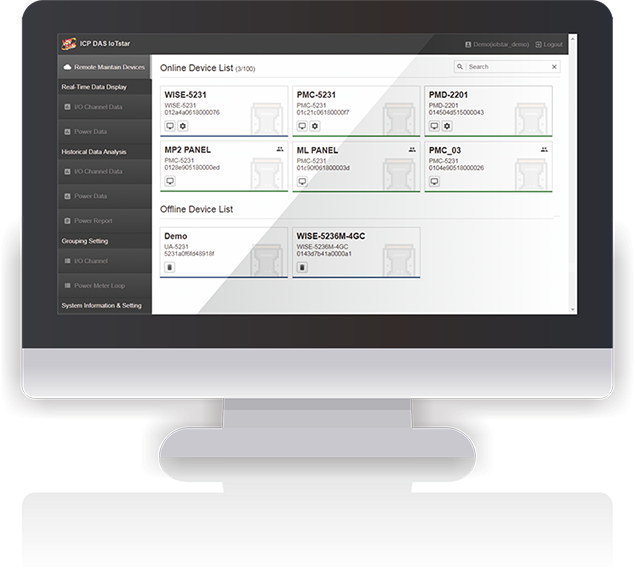

Sensor Data Visualization Service

With the built-in standard web page of IoTstar, user can directly query and review the real-time or historical sensor data (and/or Power data) collected from the WISE/PMC/PMD controllers.

IoTstar also provides IoTstar Dashboard Service package (Option). Through the Dashboard editor and a variety of Widget components provided by IoTstar, user can quickly setup the Dashboard page for the Real-Time sensor data (and Power data) collected from the WISE/PMC/PMD controllers according to their needs to review the operation status of the application system in real time.

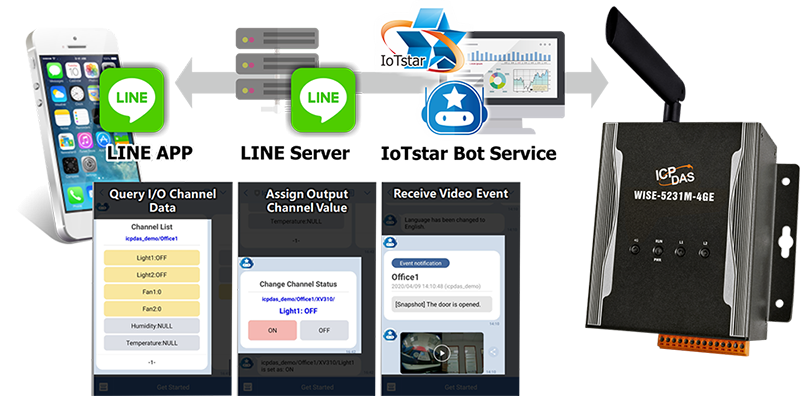

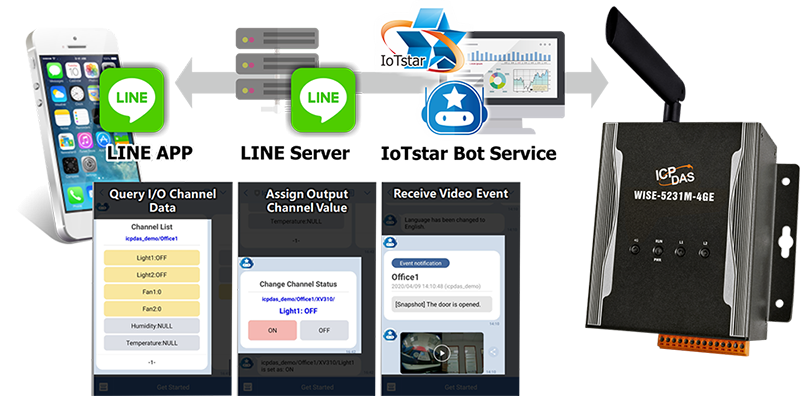

Bot Service on Controller by using Mobile Device (Option)

IoTstar provides IoTstar Bot Service package for two-way message interactions between the WISE/PMC/PMD controller managed by IoTstar and LINE chat rooms. Users can query the real-time sensor data (and/or Power data) collected from the WISE/PMC/PMD controllers and be able to change the value of DO/AO output channels anytime and anywhere by LINE App. In addition, with the iCAM IP Camera, it can also receive the video recording events on the application site, so that the users can review the operating status of the equipment through their mobile phones even they are not close by.

Why IoTstar?

By using "IoTstar + WISE/PMC/PMD" solution, the users can quickly build the IoT cloud system to perform the remote maintenance for a machine/Facility, as well as the remote monitoring of the environment. The "IoTstar + WISE/PMC/PMD" solution features the following benefits: